How Can We Help?

White Oak: Native to the entire eastern half of the United States. Its wood is a light-colored beige that is almost white when freshly cut; hence its common name.

White Oak: Native to the entire eastern half of the United States. Its wood is a light-colored beige that is almost white when freshly cut; hence its common name.

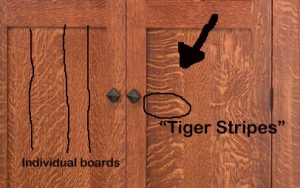

Amish craftsmen like to use quarter sawn white oak. The large trees produce wide planks that have outstanding rayflake designs (fig 6). Quarter sawn wood is very stable and white oak has a natural tendency not to rot or decay. This wood is very stable and resists cupping, twist and cracking when properly finished.

Amish craftsmen recommend using quarter sawn oak if you live in a high moisture area, as the close grain of the wood is very stable.

What is quarter-sawn lumber?

Technically, quarter-sawn lumber has the growth rings of the tree approximately perpendicular to the board’s broad face. In contrast, plain-sawn lumber has the growth rings parallel to the board’s broad face. Quarter-sawn produces both quartered and rift lumber. Look at fig. 104 and note #1; The three red lines on the right side of the photo show the growth rings of the tree and they are nearly vertical. This is a true quarter-sawn board. Figure 104, #2 shows a rift sawn board. The growth rings are approximately 30 degrees from vertical.

Technically, quarter-sawn lumber has the growth rings of the tree approximately perpendicular to the board’s broad face. In contrast, plain-sawn lumber has the growth rings parallel to the board’s broad face. Quarter-sawn produces both quartered and rift lumber. Look at fig. 104 and note #1; The three red lines on the right side of the photo show the growth rings of the tree and they are nearly vertical. This is a true quarter-sawn board. Figure 104, #2 shows a rift sawn board. The growth rings are approximately 30 degrees from vertical.

How is quarter-sawn lumber achieved?

There is only one true way to quarter saw a log. First, we cut a log into quarters (fig 104). Each quarter is then processed by cutting a single board off of one face, then cutting the next board from the opposite face, and cutting from alternating faces until the quarter is completely cut.

There is only one true way to quarter saw a log. First, we cut a log into quarters (fig 104). Each quarter is then processed by cutting a single board off of one face, then cutting the next board from the opposite face, and cutting from alternating faces until the quarter is completely cut.

What are the aesthetic qualities of quarter-sawn lumber?

The most notable characteristic of quarter-sawn lumber lies in its incomparable grain patterns. Medullary ray fleck, wavy grain and interlocked grain are all visually enhanced when the log is quarter-sawn. The revival of Mission style furniture is just one example of how today’s Amish craftsmen are rediscovering the unique beauty of quarter-sawn lumber. Today’s Amish heirloom furniture, the antiques of tomorrow, is crafted from quarter-sawn lumber. Quality reproductions and renovations of artisans’ work demand true quarter-sawn lumber. Quarter-sawn wood is the choice of Amish craftsmen.

What are the structural qualities of quarter-sawn lumber?

Quarter-sawn lumber is the uncontested winner when compared to plain- (or flat-) sawn lumber. Quarter-sawn features include:

- Reduces shrinking and swelling in lumber width.

- Reduces twisting, warping and cupping.

- Less prone to surface checking.

- Does not allow liquids to readily pass through it.

- Smooth surface as raised grain is not pronounced.

What’s the difference between quartered and rift lumber?

A quartered board features medullary ray or “fleck” perpendicular to a grain which typically forms angles from 60 degrees to 90 degrees with the board’s surface. A rift board exhibits a clean, straight, vertical grain pattern which typically forms angles from 30 to 60 degrees with the board’s surface (fig 20).

Is there a difference in cost between quartered lumber and plain-sawn lumber?

Quarter sawing is a specialized technique requiring more time and greater skill to produce. Logically, lumber prices are slightly higher than plain sawn.

If quarter sawing is so good, why don’t all sawmills do it?

For most, the art of quarter sawing has been lost over the years, except for Amish Furniture craftsmen. Like many superior practices of the past, quarter sawing lost favor to plain sawing techniques. Plain sawing is easier, cheaper, and quicker… but it results in more waste, less grain characteristic and less stable lumber.

(763)498-7730

(763)498-7730 Livechat

Livechat